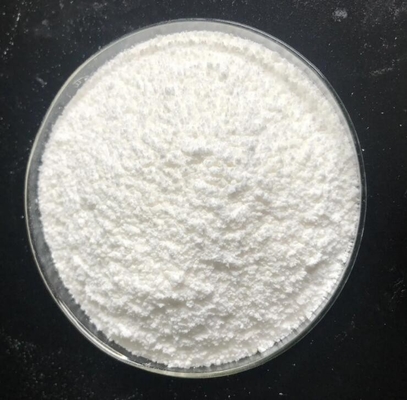

Toothpaste Sodium Carboxymethyl Cellulose E466 Thickener CMC 25kgs

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Color | White | Type | Thickeners |

|---|---|---|---|

| CMC | Application Of CMC In Washing | Appearance | Light And Free Flowing Powder |

| Viscosity | 6000 | Qty In 20' FCL | 16MT |

| CAS No | 9000-11-7 | PH Value | 6.5-8.0 |

| High Light | Toothpaste Sodium Carboxymethyl Cellulose,25kgs Sodium Carboxymethyl Cellulose |

||

Sodium Carboxymethyl Cellulose (CMC)

Sodium Carboxymethyl Cellulose (CMC) can be use in toothpaste. It can be provide the high viscosity to toothpaste.

Application of CMC in food

| ITEMS | STANDARD | |

| Moisture (%) | ≤ 10% | |

| Viscosity(2% solutionB/mpa.s) | 6000 | |

| PH value | 6.5-8.0 | |

| Chloride (%) | ≤ 1.8% | |

| Degree of substitution | 0.65-0.85 | |

| Heavy metals Pb% | ≤ 0.002% | |

| Iron | ≤ 0.03% | |

| Arsenic | ≤ 0.0002% | |

Sodium Carboxymethyl Cellulose (CMC) has function of thickening, emulsifying, suspension, water retention, tenacity strengthening, puffing and preservation in food. In food, it can improve taste, promote product level and quality and prolong storage life.

Functions of CMC in food

Thickening property: get viscosity under low concentration

Water-retaining property: reduce syneresis of food and prolong shelf life

Dispersing stability: keep food quality

Filming property: develop a layer of film on fry food

Chemical stability: stable to chemical drugs, heat and light

Properties of food CMC

Even molecular distribution

High acid resistance

High salt resistance

High degree of substitution

Low content of gel

Same property with guar gum

Acid resistant food grade CMC models: FL100, FM9, FH9, FVH9, FH1200, FH1500, FH3000A, FH6000A, FH6000G

Common food grade CMC model:FH6, FVH6, FH3000, FH5000, FH6000, FH8000, FH10000

Applications in bread and bun making

Sodium carboxymethyl cellulose has certain hydrophilic and rehydrophobic properties and is therefore used in the production of pasta products.

(1) Application in bread

As there are hydrophilic groups in sodium carboxymethyl cellulose, it can combine with water to form hydrophilic colloid and absorb water and swell when mixing with dough. After swelling, CMC-Na can increase the water-holding capacity of gluten, which is conducive to the rising of bread and the retention of carbon dioxide during baking, thus making the volume of bread bigger, but the amount of sodium carboxymethyl cellulose cannot exceed 6%. Due to its strong water-holding properties, a suitable addition can reduce the hardness of the bread. Tests have shown that adding the right amount (2% to 8%) of sodium carboxymethyl cellulose has a significant improvement on the quality of baked bread, with the best result being achieved at 6%, followed by 4%. It can increase the volume of bread, improve the structure and flavour of bread and can extend the shelf life of bread. This offers the possibility of adding sodium carboxymethyl cellulose to bread to improve its quality.

(2) Application in bun making

The amount of sodium carboxymethyl cellulose added has little effect on the pH value in the dough of wheat buns. Studies have shown that sodium carboxymethyl cellulose can effectively improve the texture of wheat buns and effectively reduce the hardness, adhesiveness and chewiness of buns, and the best performance of each texture index is achieved when the amount of sodium carboxymethyl cellulose added is 0.06%~0.08%. And now the application of sodium carboxymethyl cellulose in steamed buns is still relatively small, which also provides the possibility of its application in new fields and can increase its application scope.